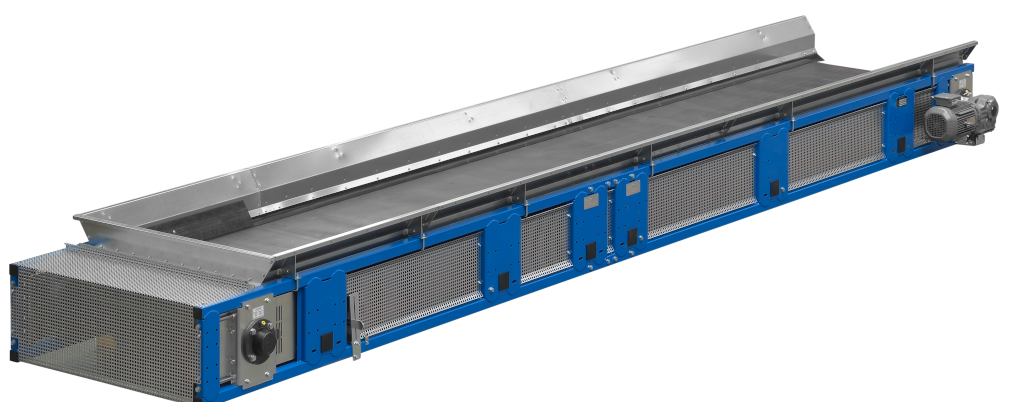

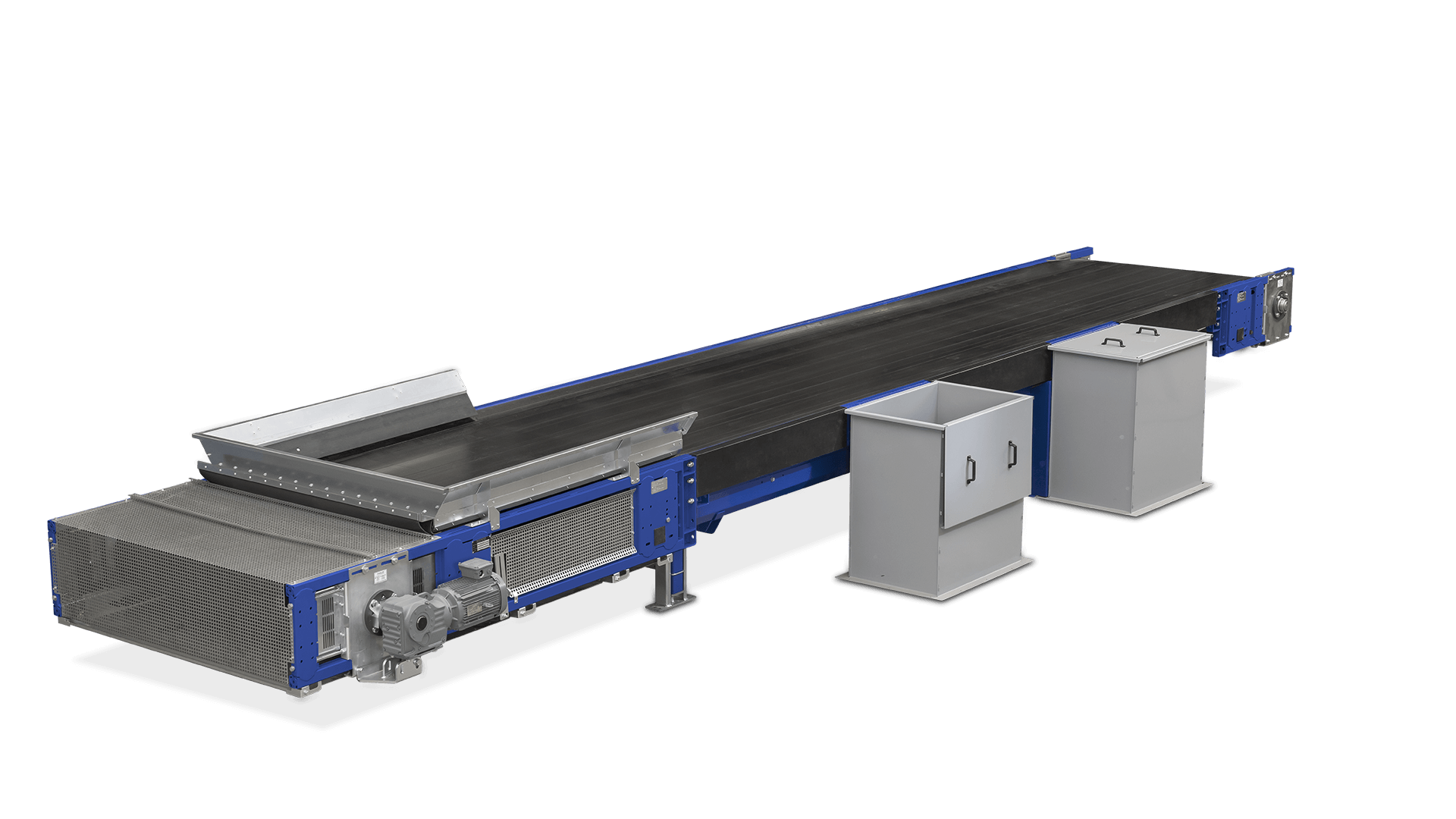

Conveyor type GG

For flows of light to moderately heavy materials and average centre distances, together with compact design.

- Robust steel table and sliding belt support

- Available with four different side-wall heights and seals

- Robust scraper made of steel or vulcanised rubber – depending on the flight design

- Space-saving SEW bevel gear motors

![STADLER conveyor type MF [Translate to EN - US:] [Translate to EN - GB:] Stadler Förderer Typ MF](/fileadmin/user_upload/5_komponenten/F%C3%B6rdertechnik/Conveyor-type-MF_1920x1080.png)

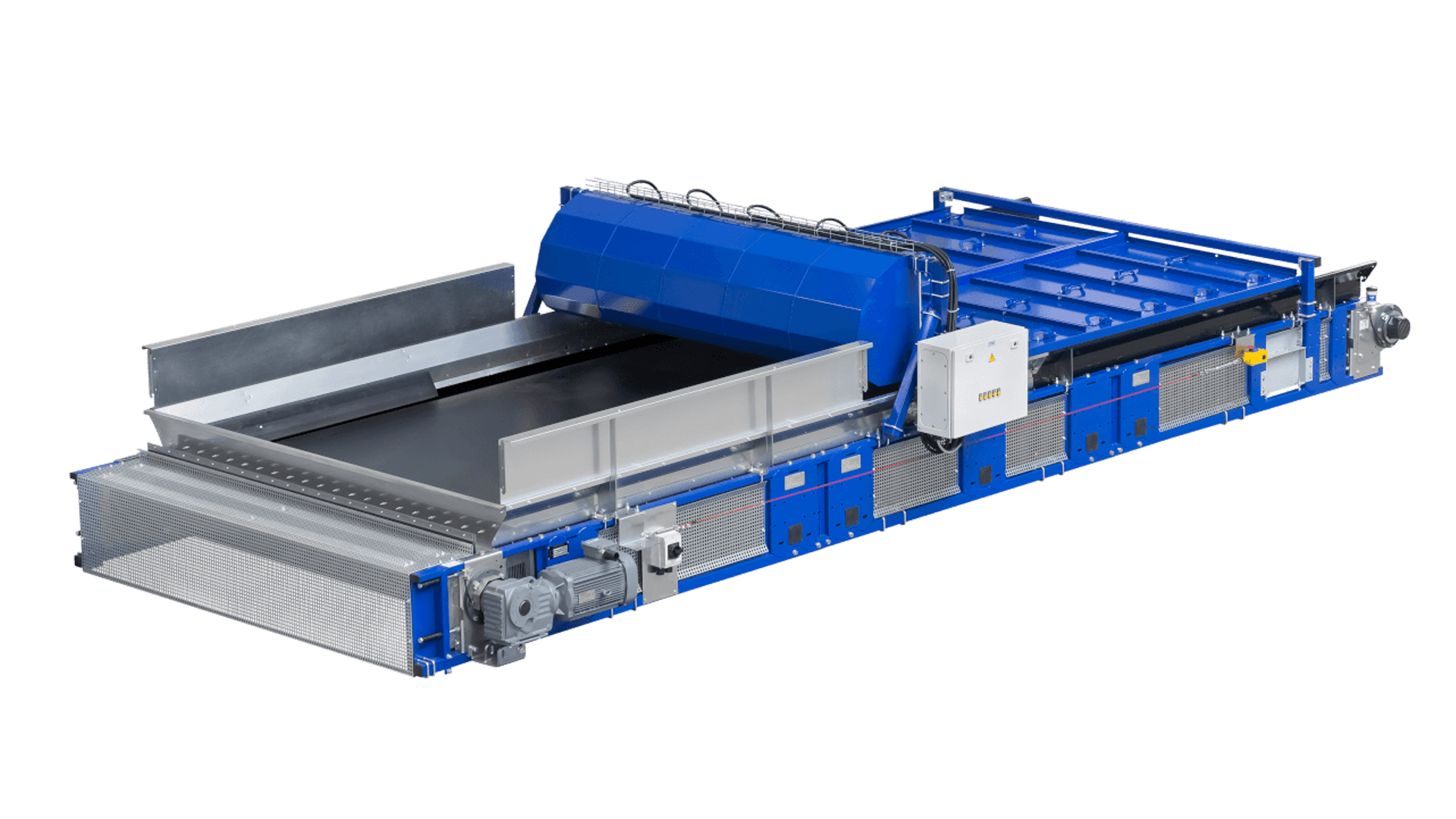

Conveyor type MF

For flows of moderately heavy to heavy materials and long centre distances – with low drive powers at the same time.

- Rolling belt support on three-part support units

- Available with three different side-wall heights

- Robust scraper made from various steel grades or vulcanised rubber – depending on the flight design

- Space-saving SEW bevel gear motors

Conveyor type PX

The STADLER conveyor PX has been specially designed for use with sensor-based sorting technology.

Thanks to conveyor speeds that can be precisely controlled, it effectively spreads the flow of material. With the stabilizer (optional), the air flow produced by the fans guide the material in a steady way on the belt, regardless of the high speed.

- Special side wall sealing for operation at high conveyor speeds

- Expansion hood with integrated maintenance platform available as an option

- Special support rolls and balanced drums for low-vibration operation

- Higher speeds for film/paper with the use of the optional stabilizer

- The standard version includes a slot for a sensor under the belt; optionally an optical sensor can also be used

- Space-saving SEW bevel gear motor with sliding movement to create space in the area of the conveyor’s head end

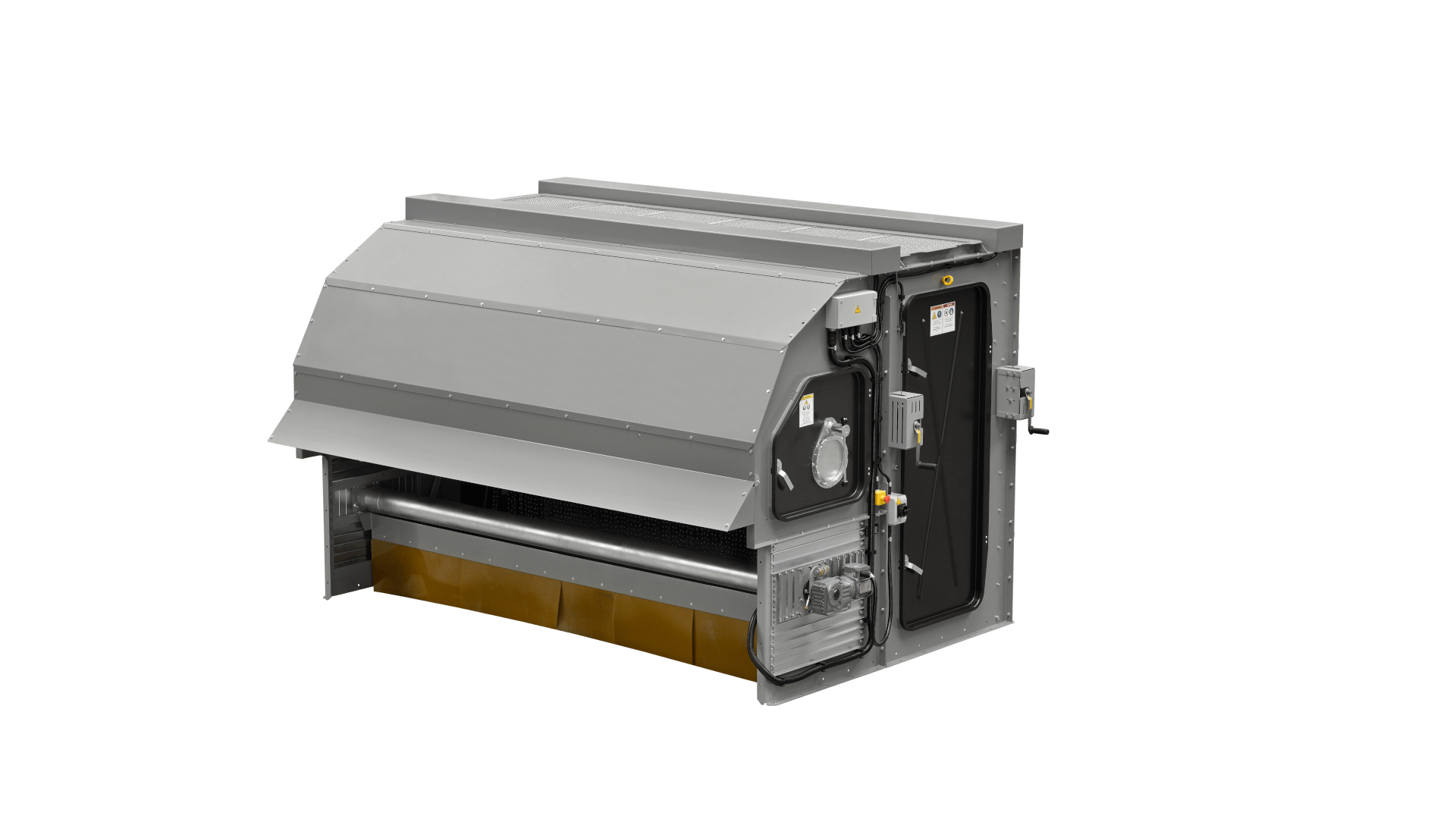

Hood type EH

For material and air control in sorting systems with compressed air discharge of one or two fractions.

- An adjustable separating splitter allows optimisation of the separation process

- One maintenance access point and one maintenance opening are located on both the left and right side of the hood

- Integrated maintenance platform with fixed position inside the hood

- Different units and conveyors can be connected to the EH via an adapter.

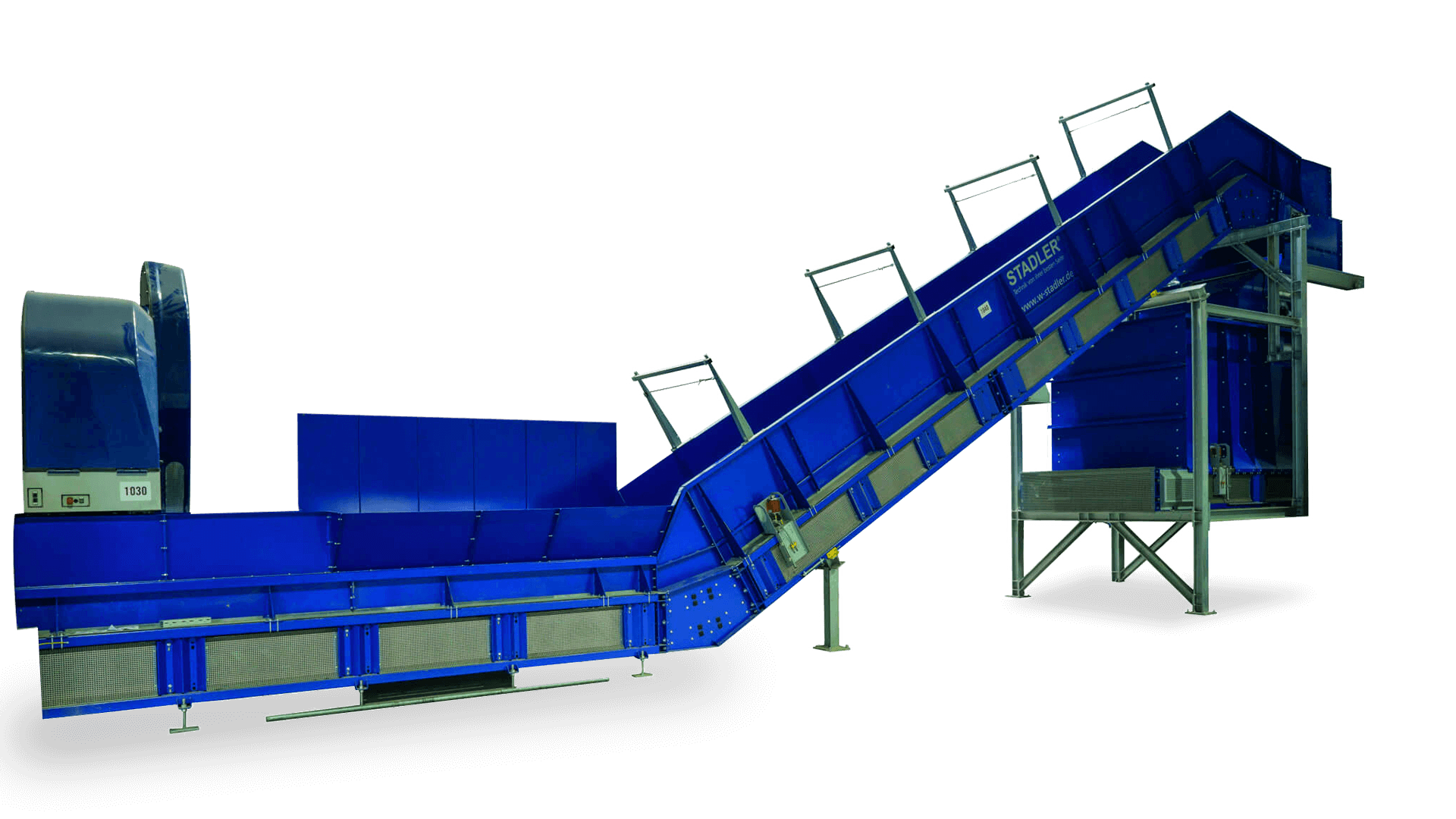

Conveyor type KF

Bush conveyor chains allow flows of even heavy and large materials to be transported with ease.

- The use of sturdy lateral sections and various chain and belt designs enables the STADLER chain conveyor to transport whatever material is required

- The KF can be used as an infeed conveyor, a baler feed conveyor or a feed hopper, depending on how the angular sections are positioned

- Space-saving SEW bevel gear motors

- The drive and return shaft can be removed laterally, forwards or backwards.

Conveyor type SO

The side wall and belt position have been specially designed to sort material as efficiently as possible directly on the conveyor.

- Discharge chutes that can be flexibly positioned allow sorting of different fractions

- The ergonomic design of the frame enables a comfortable working position

- Adaptable belt speeds for optimum sorting results

- Space-saving SEW bevel gear motors

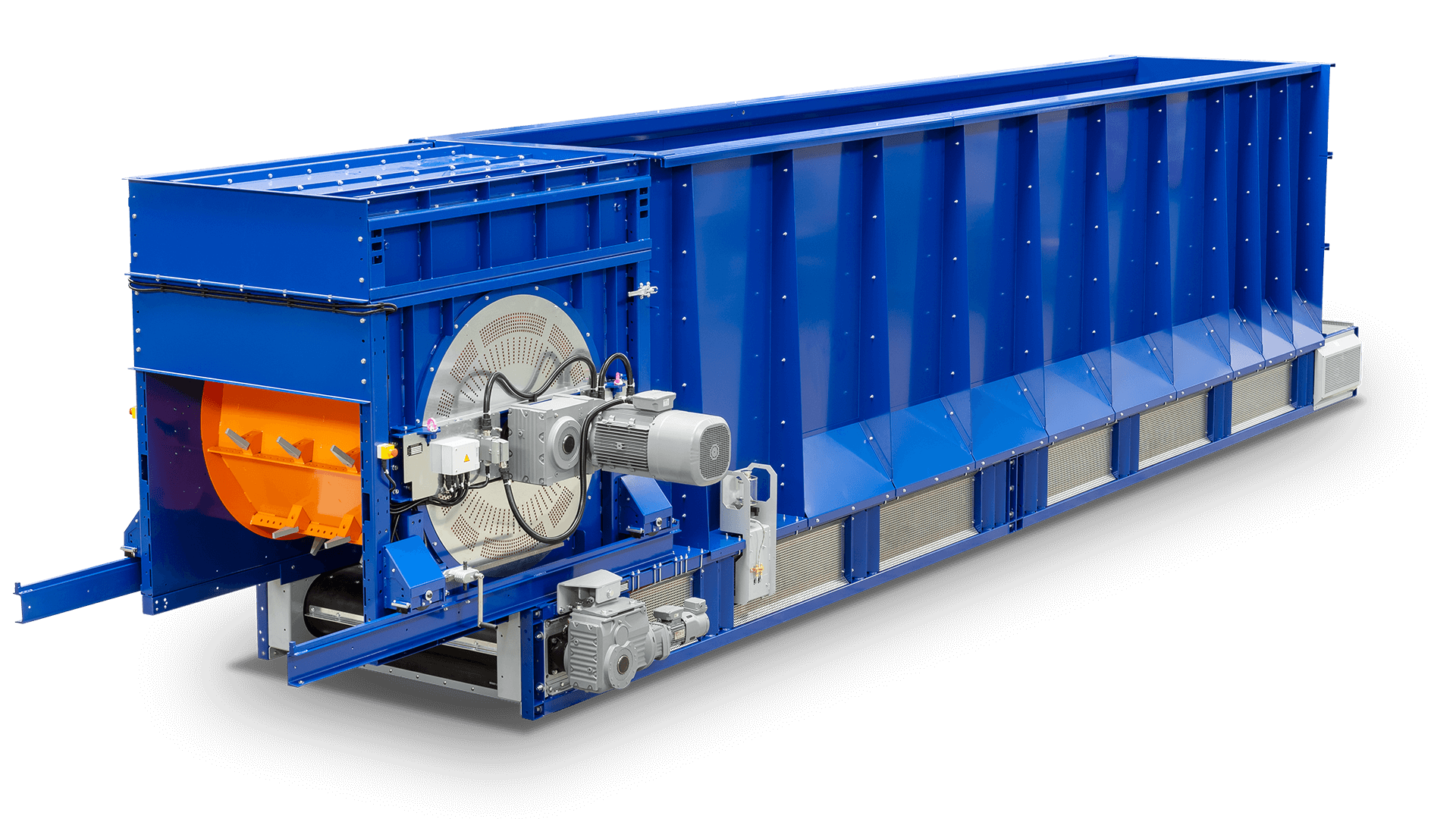

Conveyor type BU

Developed for temporary storage of sorted material fractions, the STADLER storage conveyor has side walls up to 2.5 metres tall.

- Rolling belt support means heavy materials can be accomodated in the storage area

- Thanks to robust doors made of steel segments, the entire storage capacity can always be fully utilised

- Space-saving SEW bevel gear motors

Dosing system type DK

The material is evenly distributed and thus ensures a constant feeding of the system and higher purity.

- The system consists of a combination of our DW metering drum and our KF chain conveyor in the bunker version, whereby dosing and storage of the material is made possible

- Reliable material distribution

- Large maintenance opening due to moving unit – blockages and wraps can be removed even in the filled state

- The working height of the drum can be adjusted to different heights (100 mm steps)

- Lateral removal of the rotor body possible