STADLER experience

“STADLER commissioned the first plant of this type back in 2008. Since then, more than 25 such STADLER sorting plants have gone into operation, with installations in France, England and the USA in particular.”

Material properties

Nowadays, separation of the organic fraction from recyclable materials takes place in many countries around the world. However, the dry mixed recyclables contain greatly differing components depending on the country.

For STADLER, this means it is necessary to devise the best possible overall plant concept for each type of material.

The average composition exhibits an approximate density of 80 kg/m3. Since paper and cardboard have by far the highest density in this mixture, the overall density varies depending on the proportion of these two recyclables.

Because the proportion of films and plastic trays in the total volume is constantly increasing, both the composition and total density will change in the future.

Example process description

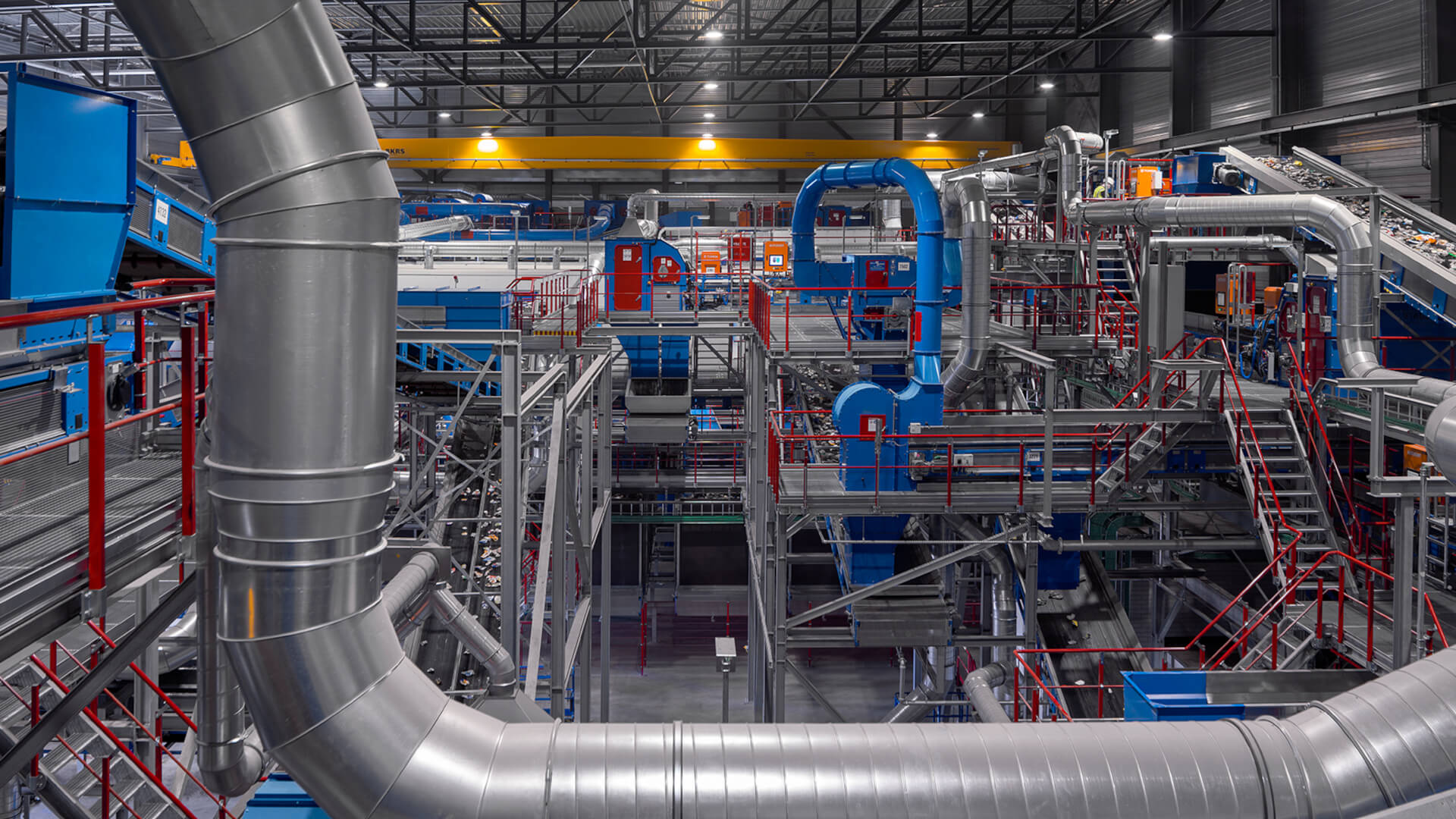

After the plastic bags have been mechanically opened, the material is divided into the previously defined grain size and shape using a trommel screen and ballistic separator. Sorting of the individual materials is carried out with the aid of special optical systems. If required, the fraction purity can be optimised by manual sorting in a sorting cabin. The sorted fractions are pressed into bales for volume reduction and improved handling during transport.

Main components

- Bag opener

- Trommel screen

- Ballistic separator

- Near infrared technology NIR

- Overbelt magnet

- Eddy current separator

- Windshifter

- Sorting cabin

- Baler

- Container press

- Can press

- Conveyor

- Steel construction with walkway

- Electrical engineering

Output fractions

- Ferrous metal

- Film

- Fine grain

- Mixed plastic

- Non-ferrous metal

- Paper / paperboard / cardboard boxes

- PE

- PET bottles

- PET trays

- PP

- PS

- Refuse derived fuel

- Small film

- Tetrapak

References